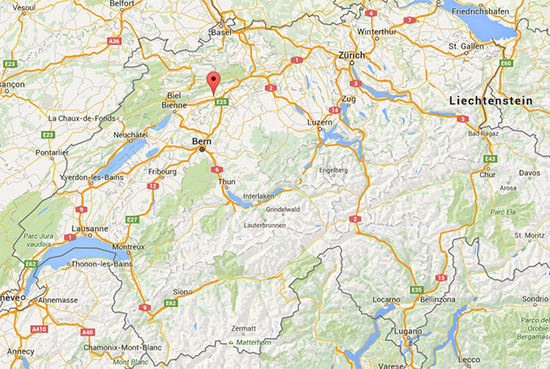

The STORE&GO demonstration site at Solothurn, Switzerland

Final operation data at the project end

At the heart of the STORE&GO project were the three demonstration facilities. The facility at Solothurn, Switzerland used the biological methanation process, where methane is produced by mikro organisms (archaea) that use the hydrogen from the electrolysers and the carbon dioxide from a waste water treatment plant. Starting in May 2019, the facility produced synthetic methane and injected it into the urban gas distribution grid.

Following are the operation data of the Solothurn plant during the course of its runtime in the project.

| Operating hours | 1299 h |

| Injection | 1057 h |

| SNG-Output | 173.000 kWh |

In Solothurn, the methanation unit reached a product gas quality of more than 99 vol.-% of methane. During the operation of the plant, the biocatalyst was slowly adapted to higher loads: At the end of the project, the plant was capable of operation at nearly 100 % load. The overall methanation efficiency (without heat usage) in Solothurn is 73 %. The overall PtG efficiency is 76 %, which includes the usage of the low temperature (T < 60 °C) waste heat from the electrolysis. In Solothurn the nearby ‘Hybridwerk’ was able to use this waste heat at relatively low temperature, since the heat was boosted via a heat pump for district heating. The energy demand for the CO2 source was neglected, since the CO2 stream to the plant was a waste product. Further optimization potentials is the integration of the waste heat from the methanation reactor in the ‘Hybridwerk’, which was planned in the project but not tested. Another potential is the reduction of the electrical energy demand of the methanation unit. If both potentials would be realised, an overall PtG efficiency of 89 % could be reached. This shows that the efficiency of the overall a PtG process chain is very dependent on the local conditions and requirements.

4. May, the first STORE&GO „Ground-Breaking“ event in Solothurn, Switzerland

On Thursday, May 4, 2017, the construction work (Ground-Breaking) on the Power-to-Gas research facility was started in Solothurn, Zuchwil. The plant, which is built and operated by Regio Energie Solothurn, involves five other partners in the STORE&GO project of the EU research and innovation program “Horizon 2020”.

More than 30 stakeholders attended the event among them numerous journalists and partners from the project. Felix Strässle, Director of Regio Energie Solothurn, welcomed the audience followed by a presentation about the Power-to-Gas plant. Subsequently, the project partners and the audience gathered outside to perform the ground breaking of the demonstration site together, to officially start the construction work.

The Regio Energie Solothurn has been operating the hybrid plant on the Aarmatt- Area southeast of the city Solothurn, for about two years. The plant uses the connection between their supply networks electricity, gas, water and district heating – also known as network convergence. Energy will be converted from one form to another and stored in one of the networks for e.g. to convert summer surplus electricity from photovoltaic systems and store it for the winter, e.g. to use it during the winter for heating. This conversion takes place in the electrolyzer via the so-called power-to-gas process.